The desired aroma and flavor of coffee is developed during roasting, during which the beans undergo a series of complex chemical reactions that lead to physical transformation and chemical properties. In the first part of this two-part series, we’ll learn more about the physical transformation to the beans inside the roaster starting with the change in bean structure, the release of steam leading to the buzzing sounds. crack and grain color change…

Coffee is removed from the roaster

1. The basis of physical transformation when roasting

Coffee beans have the highest density and cellular diversity of all plants in the family, which is a prerequisite for all the flavor variations we desire. Without a specific physical structure, the chemical reactions necessary for taste and aroma would not take place.

In The Craft and Science of Coffee, Britta Folmer points out that you can’t roast ‘green coffee powder’ in the same way as whole bean coffee (sounds obvious right?). This is to emphasize that the whole coffee bean is similar to a “minireactor” that allows essential chemical reactions to take place. Each particle will control the reaction environment in such a way that the precursors will decompose, transform, combine… in the right order.

2. Physical Structure

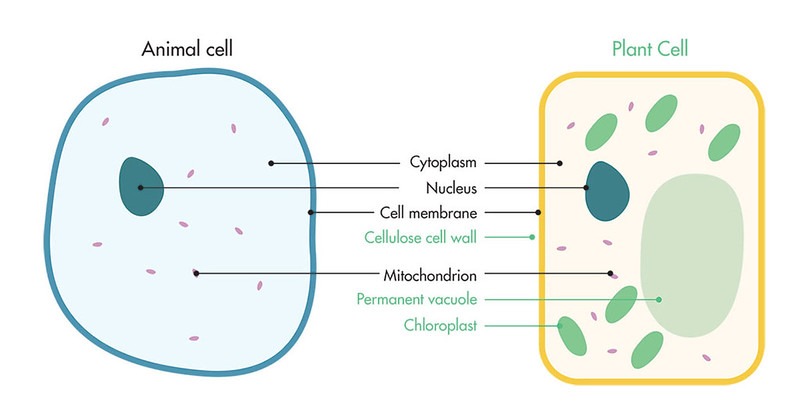

Every plant (and animal) cell has a cell membrane, in the case of the coffee bean, which is composed of cellulose and some other carbohydrates. These cell walls act as a ‘vegetal skeleton’, forming a very strong structure. If we extract about 20% of the solids in each coffee bean into an espresso, most of the remaining 80% is this cellulose framework.

In the case of green coffee beans, the cell wall is about 10 micrometers thick, the cell itself is about 20 to 30 micrometers in size, and the vacuole occupies about half the cell volume – Dr. Monika Fekete – Founder of Australian Coffee Science Lab

Typical animal (left) and plant (right) cell structures

Second, most plant cells take the form of an empty ‘pocket’ in the middle called a permanent vacuole. The vacuole space for coffee beans is very large, can occupy more than half of the cell volume. Their main job (when the seeds are still alive) is to retain water or nutrients such as proteins, fats and carbohydrates… After undergoing roasting these ingredients become the main flavor compounds.

Compared to other roasting processes in food applications (beans, cocoa, etc.) roasted coffee requires the highest temperatures to develop desired properties. In general, the bean temperature is usually above 190°C for a certain minimum time to trigger the typical chemical reactions of roasting – The Craft and Science of Coffee

3. Sensory transformation

The most obvious physical transformation that occurs during roasting is color. Before roasting, coffee beans are green. Then a few minutes of heat causes the chlorophyll present in the beans to turn yellow, before triggering a further series of chemical reactions that turn the coffee beans brown – to dark brown and finally black. This process is responsible by two main groups of chemical reactions:

– First: Formation of melanoidin – product of Maillard reaction (chemical reaction between amino acids and reducing sugars)

– Second: Caramelization of the natural sugars (breakdown of carbohydrates) in the seeds.

Coffee color throughout the roasting process

Although the color of coffee beans will continuously change from green to yellow, brown, dark brown to black. But because the transition from yellow to brown takes place at the end of the roasting process with a very short time, and the classification according to the color scale quite complicated, so we will summarize the five main levels as follows:

Cinnamon > Light Roasts > Medium Roast > Medium-Dark Roast > Dark Roast

Color and flavor development

The first issue to consider here, is that the development of flavor inside the coffee bean always progresses later than understanding the color outside the hat. Therefore, a skillful artisan must manage this process and ensure that the internal flavor is fully developed as the color reaches its grain. And it should be noted that, in the first half of the process (Light roast) the difference between the color expression and the growth inside the grain is not significant, the later (Dark roast) this difference is larger.

Second, it should also be noted that a darker roast does not make the coffee grow more. On the other hand, a light roast does not mean that the coffee is fully developed. Color, is only part of the expression for taste. So, with the right development, any color of the roasting process can give a rich and rich flavor.

In a convenience store, you can find your choice of Light or Medium roasted coffee, but you’d have a hard time using these words to describe coffee at a mainstream specialty coffee shop. They work with the knowledge of the origin of each bean to find a Roast Profile that represents the full quality potential of that bean.

4. Structure, moisture and weight of coffee beans

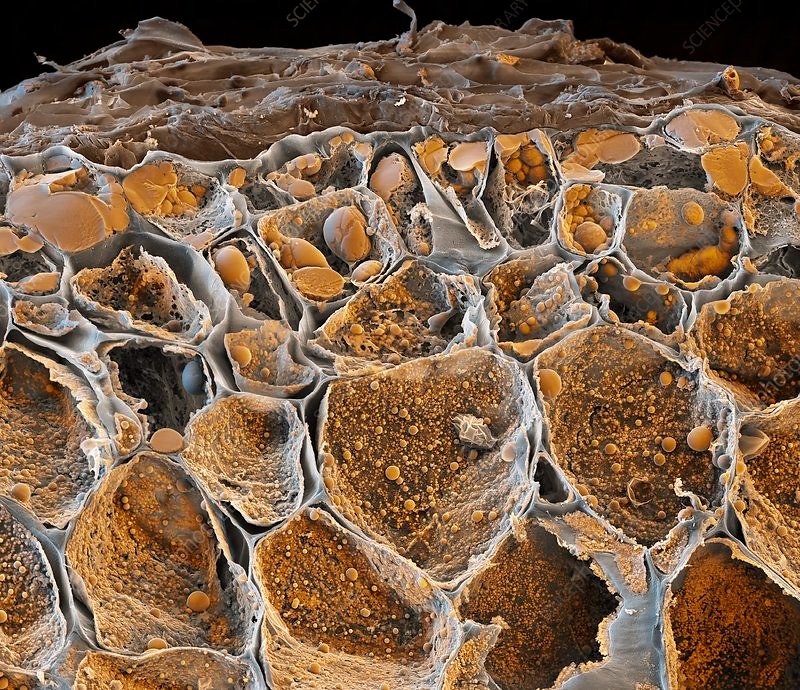

As mentioned above, the microstructure of a coffee bean is a matrix of cells made up of cellulose. The roasting process destroys the coffee cell structure, although the framework of the cell walls remains intact, the diminished cytoplasm pushed towards the cell wall, making room for a gas-filled void in the region. center. This cell wall layer becomes thinner as roasting continues, the gases and steam will increase pressure causing the cell size to increase. Therefore, in parallel with the increase in volume, the measured porosity also gradually increased during roasting.

Simulate the voids inside coffee beans after roasting, with the accumulation of a multitude of soluble & insoluble compounds

During roasting, the free water in the beans evaporates and creates a high pressure in the beans. This swelling will change the structure of the cell walls from rigid to more flexible, the granules will gradually weaken, become softer and more porous, and due to the pressure of intracellular water vapor (and other gases) the The material inside will be forced out of the cell wall leaving an intracellular void. Most of these gaps will be filled with CO2 – when water penetrates these cavities during the preparation process, the dissolved compounds will follow the water into the extract and give us a taste of the coffee.

4.1. Loss of moisture during roasting

Throughout the roasting process, coffees will lose 12%-24% of their own internal weight; depending on the initial moisture content (and the degree of roasting at the end). Since the first crack appeared, it marks the coffee has lost 11%-13% by volume. About 30 seconds after the first crack ends, it’s about 14% -16%. And at the beginning of the second crack, the coffee has lost 17%-18% by volume (*). In the specialty coffee industry, with a priority given to preserving the beans’ native flavors, most roasters keep their beans “lost” at an average of 14%-16% by weight. their initial amount.

With the above weight loss – water accounts for 90% of the lost weight. The remainder is organic matter that released in the form of CO2; as well as small amounts of carbon monoxide, nitrogen, aromatic compounds and volatile acids. Loss of organic matter increases more significantly from medium roasts; with loss of organic matter from 5 to 8%, and up to 12% from dark roasts onwards.

4.2. First crack & second crack

When the steam pressure in the coffee beans is constantly increasing between 100 – 160°C, the steam pressure will break the grain structure (physical transformation) to create a “bang” that we call First crack. At this point, the beans can double in volume, depending on the degree of roasting, the moisture content in the beans will drop from the original 10-12% to about 3-5%.

After the first crack, the structure of the coffee beans becomes more brittle; which will set the stage for the second crack (about 225 – 230°C). But the ‘second bang’ does not result from the release of free water present in the grain as it does for frist crack. That is because the remaining water in the grain has participated in the decomposition reaction. So the second crack mainly caused by the release of pressure caused by CO, CO2, NOx and other substances.

4.3. Fat during roasting

It would be remiss to mention only the participation of water in the roasting process and forget that 16% of the dry weight of green coffee is lipids (mainly triglycerides). And because they are difficult to evaporate, during roasting; under high pressure in the seed these compounds move from the center of the cell. Coincidence is that it is thanks to the thin layer of lipids that cover the beans ; most of which are essential to creating the aroma of coffee, without oil they cannot. dispersed in the extract.

In Dark roast – more oil on the surface of the coffee

In some cases, coffee beans can contain up to 18% lipids. Lipids present in the cytoplasm of the coffee bean; they protected by a separate membrane along the cell wall. Physical transformation in the structure of coffee bean tissue during roasting will destroy the biological organization of the bean cells. Along with the increase in gas pressure inside the bean; the coffee oil pushed through the small microvessels in the cell wall to the surface of the bean. In the process of moving to the surface of the seed, many small oil droplets appear; which will gradually coalesce and become thicker, eventually covering the whole seed with a shiny film of oil.

Physical transformations in coffee bean structure go one way to account for the shift from green coffee – to roasted coffee; but on another (or more accurately, another front). The chemical change that occurs during roasting is the “molecular basis” that forms the flavors; promoting the physical transformation, which is also one of the areas where understanding is lacking. of the coffee industry.

——————————————————————————————————-

We are here to match your requirement. Do not hesitate to contact us for the best price!

PRINCE COFFEE

ADD: 41/49 Huynh Thuc Khang Street, Dong Da District, HaNoi, VietNam

EMAIL: sales@fineco.com

HOTLINE: +84 966420187 (WHATSAPP/VIBER/ZALO)